Aerofit designs and manufactures high and low pressure fluid fittings and fitting systems for aerospace, marine, nuclear and other critical industries. Headquartered in Fullerton, CA, the company is a market leader in both separable and permanents fittings with fully internalized engineering, manufacturing, processing and testing facilities.

Our Products

Axial Swage

Aerofit is QPL approved for axial swaged fittings per specification AS5958, Axially Swaged Tube with Flareless Separable, Fluid System 5080 psi. Our approval includes titanium alloy per AM4928 in sizes -04 through -20. We are also approved in Airbus axial swaged standards and currently qualifying with other OEMs. Products will be available in aluminum.

Radial Swage

Radial swage fittings are available under both customer and industry standards. Aerofit has received QPL approval for AS part numbers and is qualified to OEM standards. Parts are available in 21-6-9 CRES per AMS5656 and 6061-T6 or T651 Aluminum per AMS-QQ-A-225/8 or AMS-QQ-A-367 in sizes -04 through -16.

Welded

Types include a variety of integral weld lip and butt-weld fittings in various configurations. Aerofit manufactures parts that meets the procurement specification AS1576 and customer requirements. We provide weld fittings under industry standards and customer standards.

Flareless

Aerofit offers a variety of industry standard hardware under AS, MS, NAS, and customer part numbers. Parts meet the requirements of AS18290, AS85421, AS85720 among others and is available in tees, elbows, crosses, adapters, unions, and reducers. We offer the most QPL approvals of any fitting manufacturer.

Beam Seal

Our beam seal fittings are qualified up to 5000 psi operating pressure and are available in titanium and stainless steel under both industry and customer standards. Parts meet requirements of AS85421 and AS85720. Higher operating pressures are available upon request.

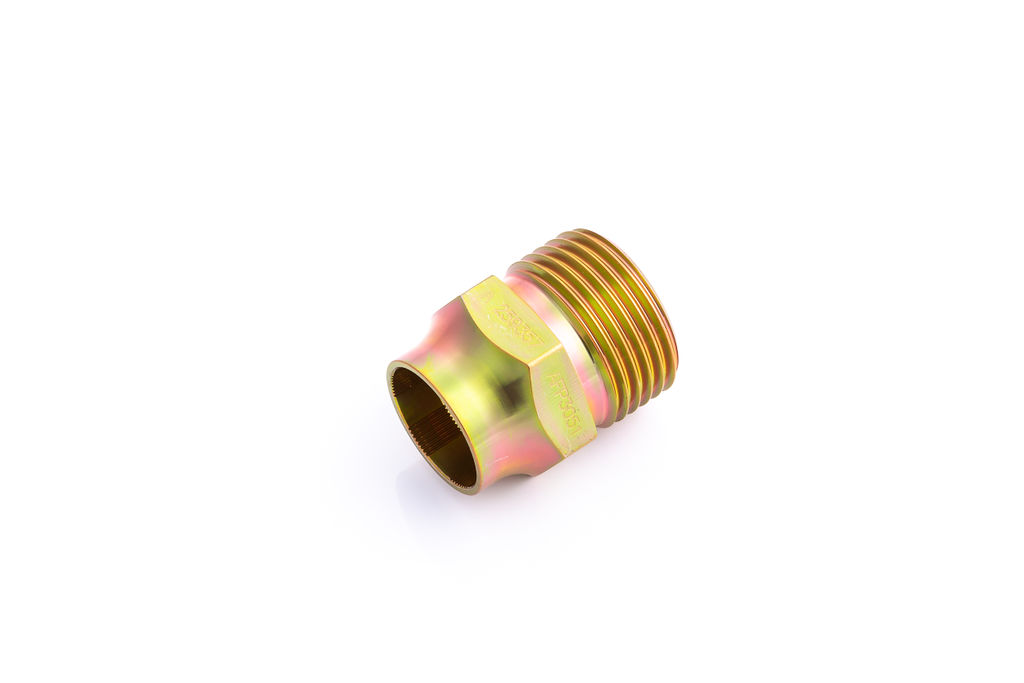

Ring Lock

Ring lock boss port fitting adapters are available in beam seal, flareless, and flared designs. The serrated locking made from A286 stainless steel provides an interference fit between the boss port and the adapter, preventing rotation and loosening in high vibration and thermal cycling environments.

SMA

Shape Memory Alloy (SMA) fittings utilize a special material that exhibits a metallurgical phase change when heated or cooled. This reduces the manufacturing throughput and the need for expensive welding or swaging tooling.

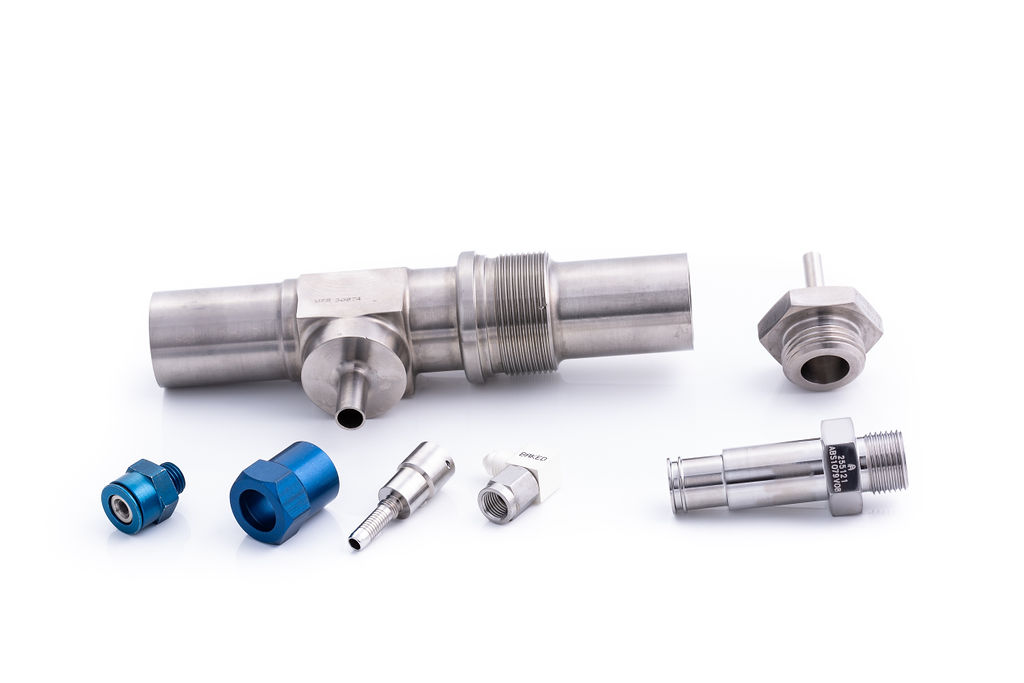

Special

Aerofit offers prototype and one-off special precision machined parts. We provide hardware requiring turning up to 4" in diameter and up to 14" in length. We work with Aluminum, Titanium, Stainless Steel, inconel, Hastelloy and Waspaloy.