Our Products

At CAM we believe in delivering value in all that we do, for our customers, for our employees and for our stakeholders.

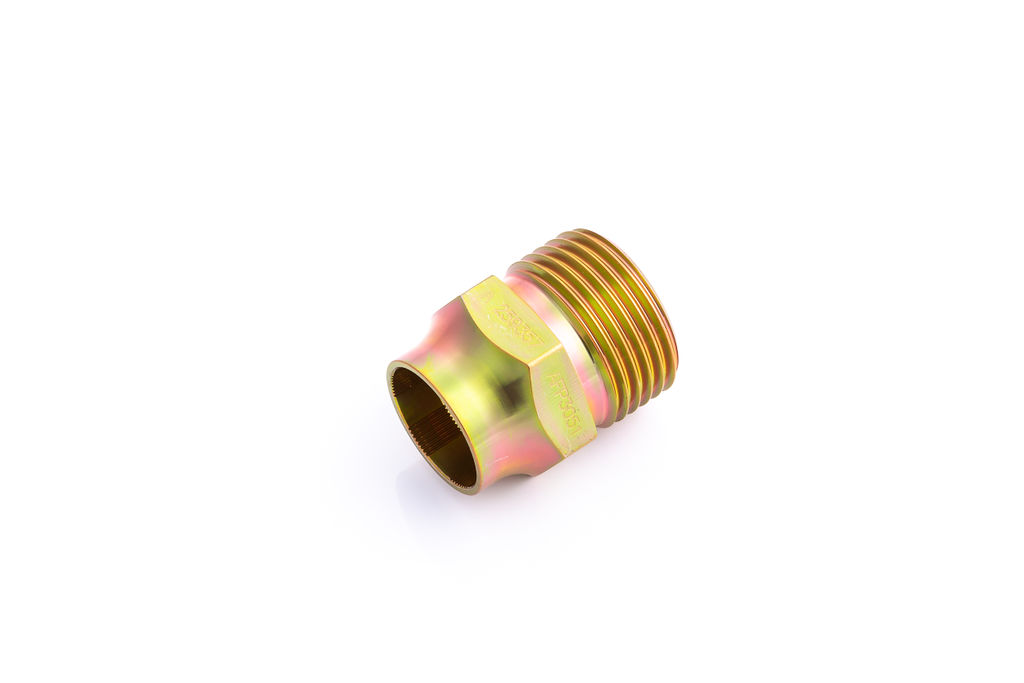

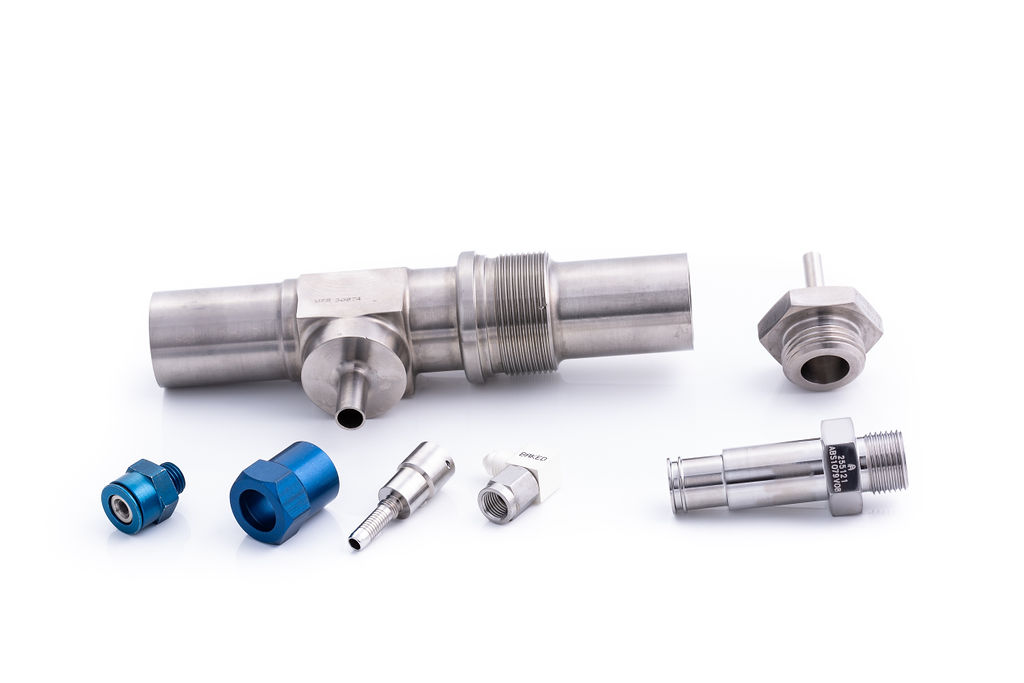

Fittings

We design and manufacture high and low pressure fluid fittings and fitting systems for the aerospace, marine, nuclear, and other critical industries. We provide individualized customer service from in-house and on-site technical support to application evaluation and product design.

Axial Swage

Aerofit is QPL approved for axial swaged fittings per specification AS5958, Axially Swaged Tube with Flareless Separable, Fluid System 5080 psi. Our approval includes titanium alloy per AM4928 in sizes -04 through -20. We are also approved in Airbus axial swaged standards and currently qualifying with other OEMs. Products will be available in aluminum.

Radial Swage

Radial swage fittings are available under both customer and industry standards. Aerofit has received QPL approval for AS part numbers and is qualified to OEM standards. Parts are available in 21-6-9 CRES per AMS5656 and 6061-T6 or T651 Aluminum per AMS-QQ-A-225/8 or AMS-QQ-A-367 in sizes -04 through -16.

Welded

Types include a variety of integral weld lip and butt-weld fittings in various configurations. Aerofit manufactures parts that meets the procurement specification AS1576 and customer requirements. We provide weld fittings under industry standards and customer standards.

Flareless

Aerofit offers a variety of industry standard hardware under AS, MS, NAS, and customer part numbers. Parts meet the requirements of AS18290, AS85421, AS85720 among others and is available in tees, elbows, crosses, adapters, unions, and reducers. We offer the most QPL approvals of any fitting manufacturer.

Beam Seal

Our beam seal fittings are qualified up to 5000 psi operating pressure and are available in titanium and stainless steel under both industry and customer standards. Parts meet requirements of AS85421 and AS85720. Higher operating pressures are available upon request.

Ring Lock

Ring lock boss port fitting adapters are available in beam seal, flareless, and flared designs. The serrated locking made from A286 stainless steel provides an interference fit between the boss port and the adapter, preventing rotation and loosening in high vibration and thermal cycling environments.

SMA

Shape Memory Alloy (SMA) fittings utilize a special material that exhibits a metallurgical phase change when heated or cooled. This reduces the manufacturing throughput and the need for expensive welding or swaging tooling.

Specials/Misc

Aerofit offers prototype and one-off special precision machined parts. We provide hardware requiring turning up to 4" in diameter and up to 14" in length. We work with Aluminum, Titanium, Stainless Steel, inconel, Hastelloy and Waspaloy.

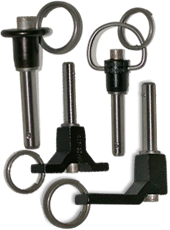

Engineered Products

A leading manufacturing solutions provider of complex sheet metal, machined solutions, complex tube assemblies, latches and quick release pins. We provide solutions to engineering challenges across a wide range of products. CAM has a staff of world-leading design & applications engineers work closely with customers in maximizing application performance, utilizing the unique technologies across our manufacturing locations.

Latches and Handles

QRP is engineered to execute at the highest level of reliability and performance. The QRP Latch product portfolio includes designs and applications for strength, durability, weight, and limited space. The QRP team provides solutions when a revolutionary idea is needed. The QRP product portfolio includes Pressure Relief Latches, Dual-Purpose Pressure Latches with manual releases, Hook Latches and Keepers, Button Latches, Hinges, Flush Latches, Pin Latches, Channel Latches, and Door Handle Mechanisms. QRP has an existing solution or can design a solution for the demands of the aerospace industry.

Quick Release Pins

Quick Release Pins are QRP's heritage. QRP has been designing, testing, manufacturing, processing, and assembling quick release pins for aerospace, military, specialty automotive, marine, and other markets since 1972. QRP can produce any variation within our existing standard approvals or any custom application that meets the quick release pin product needs of QRP’s customers.

Struts

QRP designs and manufactures struts, tie nods, and hold-open rods for both commercial and military aerospace applications. The struts, tie rods, and hold-open rods can incorporate rod-end bearings, clevises or fittings. A variety of sizes are possible. Straight or Intricate elbows or folding scissors have been designed in the past. The struts also can extend, compress, or remain fixed.

QCTLs, Adjustable Diameter Fasteners, Hinges

With a variety of capabilities and qualifications, QRP can be your strategic business partner in the design and manufacture of a variety of highly engineered products. Quick Change Track Locks provide flexibility and ease of removal and installation to facilitate a speedy reconfiguration of aircraft cabin interiors. Adjustable diameter fasteners are an excellent choice for extreme environments where high shear and tensile strength is required. Hinges made of corrosion resistant metals with a gooseneck shape provide access panel rotation.

Fasteners Self Locking

QRP manufactures a line of fasteners with a self locking feature. These fasteners are often used as retainers for avionics trays and electronic panels. QRP also produces the associated parts, like hooks and hinges.

Heat Shields

We offer landing wheel components with the exacting standards required in multiple aerospace applications. A particular core competency is the manufacture and assembly of highly precise heat shields in a variety of sizes for aircraft braking systems.

Clamps

Our band clamps are available in stainless steel, aluminum, titanium, and other materials. Built rugged for lasting service. Available in virtually unlimited diameters, with several bolt sizes and any latch style in including: standard T-bolt, quick release saddle latch and over center handles. Available to OEM, MIL/MS, and NSN/FSN Ordnance specifications.

Couplings

We offer both machined and metal formed couplings. Formed couplings are available in an extensive variety of cross-section with numerous latch styles, including T-bolt, quick-release T-bolt, and slotted, forged-trunnion designs. Designed for aircraft bleed air and environmental ducting. Available in all stainless steels, and many superalloys including 15-3-3-3 titanium for maximum strength at minimum weight. Rigid machined couplings meet both commercial military requirements and the AS1895 standard. These couplings are used with metal seals and machined couplings in high-pressure and high-temperature aircraft ducting applications such as jet engine bleed air systems.

Flanges

We offer two different styles of flanges, formed sheet metal and machined. Sheet metal flanges meet the specifications of all major aircraft manufacturers. These flanges are designed for joint sealing without the need for gaskets and are available in nickel alloy 625 and 718 materials, as well as titanium alloys for today’s lighter and more efficient commercial aircraft. Machined flanges meet both commercial military requirements and the AS1895 standard. Machined flanges are used with metal seals and machined rigid couplings in high-pressure and high-temperature aircraft ducting applications such as jet engine bleed air systems.

Complex Sheet Metal

We offer a variety of complex sheet metal formed products including roll-formed rings and stiffeners, hold-down strap assemblies, pneumatic ducting components, stamped components, shaped and rolled channels, bulge formed products, metallic seals, and deep drawn components. .

Complex Tube Assemblies

Tube assemblies experience with OD’s ranging from ¼” to 3” and wall thicknesses from 0.028” to ¼”. Experienced personnel and specialized tooling allow for large bend angles and short lengths of straight on exotic alloys with ease.

Fasteners

A global leader in the manufacture of aerospace and aircraft OEM Self Locking Nuts, Gang Channel Nuts, Standard and Special bolts, Screws, Custom Washers, Spacers and Shims.

Nuts

Products include shear & tension self- locking nuts, nut plates, and gang channel for Airframe and Engine applications in a wide range of alloys – including CRES, Alloy Steel, Aluminium, Inconel, Waspalloy, Titanium, and Multi-phase materials.

Bolts and Screws

Produced in standard, special bolts, screws to mil-spec, or customer special requirements in A-286, Titanium, and other aero alloys. Cold and warm heading of all industry head configurations, materials and recess styles. Hot forging for large diameter bolts, exotic material types, and special configurations. Product Thread Diameter range: 0-80 to 3/4; Product Lengths range: 3/16 to 10”.

Washers and Shims

Aerospace OEM and custom washers, spacers and shims including the full line of NAS, AN, MS, and BACW washers and shims. Products made from a wide spectrum of materials both metallic or non-metallic, laminated and solid materials.

Check out the new CAM shop

At CAM, we believe in delivering value in all that we do. To provide the best experience to our customers, we are pleased to introduce our online shop where you can view our products, look at your shopping history, place orders, and more.

If you would like access, please contact us to set your account up. If you have any feedback or ideas on how we can improve please let us know!

Take me there